Choosing a Windshield Stone Chip Repair Service

Ignoring that small chip in your windshield can cause more serious issues than just a small nuisance. Selecting the best repair provider is just as important as acting quickly. To guarantee that the work is done correctly and your car stays secure, it is essential to find a trustworthy windshield repair specialist. It might be difficult to decide who to trust when there are so many options available, ranging from local independent stores to nationwide conglomerates. This guide will help you make an informed choice that will safeguard your vehicle and your finances by guiding you through the crucial elements to consider when choosing a windshield repair service for stone chips.

Get An Auto Glass Replacement Quote Now 866.278.7417

Windshield Replacement & Repair

Our competitors push you into going to their shop to get your glass fixed-making it cheaper for them. We make it easier for YOU to get back on the road by offering free mobile repairs at your home or work. With our free mobile services servicing the entire Orange County & Los Angeles area, we can often handle your windscreen replacement the same day! So the next time you need a windshield replacement, give us a call.

Talk to a Windshield Replacement Specialist Now 866.278.7417

Calibration

Calibration is the process of returning a vehicle’s ADAS to OEM specifications. Calibration is necessary after a new glass installation, particularly a windshield with a camera mounted to it, to ensure that the ADAS features continue to function properly despite having been moved during installation. If a car’s ADAS is not properly calibrated, the system may not function safely. A misaligned camera could jeopardize the functionality of the system and lead to dangerous driving or accidents, so it is crucial that the cameras are aligned perfectly, which is what windshield calibration ensures.

Talk to a Calibration Specialist Now 866.278.7417

Fleet Auto Glass Repair

We provide expert auto glass repair and windshield replacement services for commercial fleets of all sizes. We are experienced with all manufacturers and machine types of domestic or foreign cars, trucks, vans, or commercial vehicles, including heavy equipment. Our same day mobile auto glass and windshield repair service will enable you to get back on the road faster and start saving you time and money instantly. Give us a call today! We are here to help!

Talk to a Fleet Auto Glass Specialist Now 866.278.7417

Why Repairing a Chip Matters

Prior to selecting a provider, let’s briefly discuss the reasons why you shouldn’t wait. A windshield is an essential structural element of your vehicle that serves as more than just a wind and rain barrier.

Safety: The windshield contributes up to 30% of an automobile’s structural strength. If your windshield weakens, your airbags may be less effective and more prone to malfunction in a rollover collision.

Cost: Repairing a little chip is significantly less expensive than replacing the entire windshield. While most fixes cost less than $100, a replacement can cost several hundred to over a thousand dollars, depending on your vehicle.

Convenience: It is frequently possible to finish a chip repair in less than half an hour. A complete replacement necessitates a curing period before the car is safe to drive and is a more extensive procedure that can take several hours.

Crucial Things to Look for When Choosing a Repair Service: Not all repair services are created equal. Utilize these standards to screen possible businesses and identify those that provide superior service and high-quality work.

Certification and Training for Technicians: The technician’s ability is the most crucial element in a high-quality windshield repair. Seek businesses that have qualified technicians on staff. The most respected certification in the industry is that of the Auto Glass Safety Council (AGSC).

AGSC-certified technicians have been trained in the latest safety standards and repair techniques. Never hesitate to inquire about the credentials of a company’s technicians.

Reputable businesses will be pleased to highlight their credentials and understand that you want the best care for your vehicle. A skilled, qualified expert is able to accurately evaluate the damage, employ the appropriate instruments, and guarantee that the repair is long-lasting and as undetectable as possible.

Quality Materials and Equipment

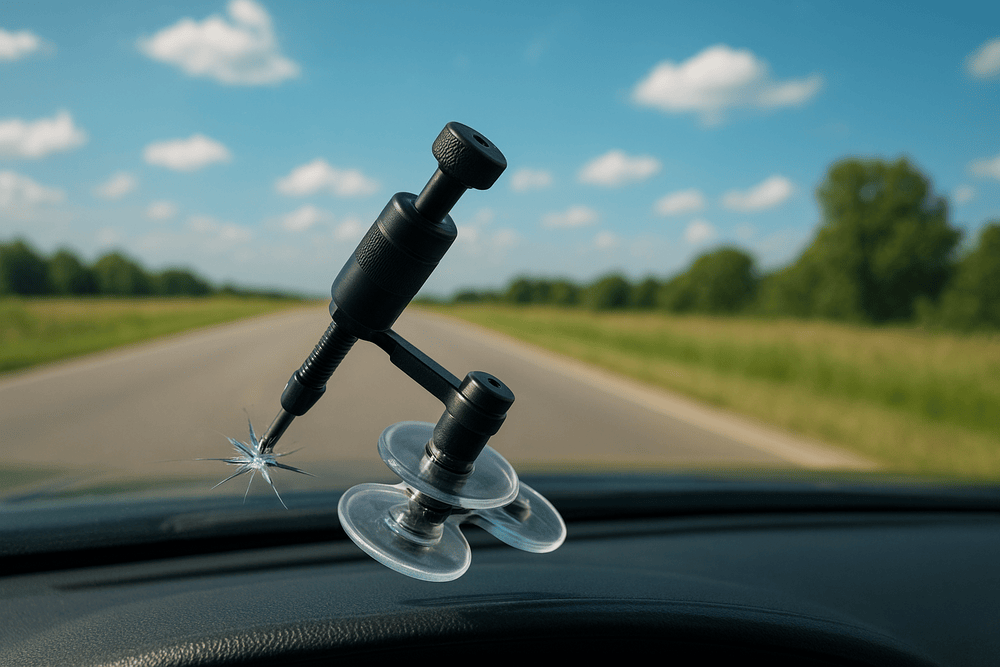

Great tools are necessary for a great technician. The caliber of the resin and the injection tools used during the repair procedure directly impact the outcome. To form a solid bond that stops the chip from spreading and repairs the windshield’s structural integrity, high-quality resin is essential.

Ask the prospective repair service what kind of resin they use when you speak with them. Professional-grade resin made especially for windshield repair is what they ought to be utilizing.

This substance is designed to have optical qualities that are comparable to those of glass, which helps to hide the repair. To ensure that the resin fills every tiny fracture, advanced injection tools are also crucial since they produce a vacuum to remove air from the chip and then inject the resin under pressure.

Options for Services: In-Store vs. Mobile: There are usually two ways to get windshield repair services: in-store or on-the-go.

In-Shop Service: By bringing your vehicle to a physical location, the technician can operate in a controlled setting away from weather conditions that could interfere with the resin’s drying process, such as rain, extremely high or low temperatures, or direct sunshine.

Mobile Service: A lot of companies offer the convenience of coming to your home or place of work. This is really helpful and time-saving if you have a busy schedule.

An in-shop repair is frequently preferred for the best outcomes, but a competent mobile technician will take care to mitigate environmental conditions. Make sure the technician has a plan in place to handle any unfavorable weather conditions if you choose mobile service.

Guarantees and warranties: A trustworthy repair company will guarantee its work. Always ask about their chip repair warranty. For as long as you own the car, a standard warranty will ensure that the mended chip won’t spread. The business should offer to use the repair’s cost toward a new windshield replacement if it spreads.

A robust warranty indicates that the business has faith in the quality of its work and the materials it employs. Avoid any service that lacks a guarantee, as it could indicate poor quality.

Do you have a Question?

Get An Auto Glass Replacement Quote Now 866.278.7417

Insurance Processing

Windshield chip repair is frequently covered by comprehensive auto insurance without a deductible. This is due to the fact that insurance companies would prefer to cover a minor fix now rather than an expensive replacement later.

An expert repair business will handle insurance claims in a more efficient manner. They ought to be able to confirm your coverage and send a direct charge to your insurance provider, saving you the trouble.

Inquire up front if they cooperate with your insurance company and what details they require from you to initiate the claim. This ease of use may be a decisive element.

Internet Reputation and Reviews: It’s simple to check a company’s reputation in the internet era. Verify reviews on platforms like Google, Yelp, and the Better Business Bureau (BBB).

Listen to what customers have to say about the repair’s quality, the professionals’ professionalism, and their overall experience receiving customer service. Any business may occasionally receive unfavorable reviews, but it’s important to monitor any trends.

Clear warning indicators include persistent complaints about repairs not working, inadequate communication, or unstated costs. On the other hand, a solid indication of a reliable company is a lengthy history of good reviews.

What You Should Do Next: Immediate repair is necessary for a stone chip in your windshield. By methodically selecting a repair service, you can ensure correct work and maintain the safety and aesthetics of your car.

Seek out a company with a strong reputation, certified staff, high-quality materials, and a good warranty. You’ll feel more at ease and avoid future expensive issues if you take the time to conduct thorough research. Avoid waiting for that tiny crack to grow into a larger one.

What Matters for Safety Quality and Cost

The three pillars of safety, quality, and cost tie everything together, whether you’re managing a building project, a manufacturing plant, or a healthcare center. If you make a mistake with one, the others suffer.

You risk severe repercussions if you ignore any one of the three: injuries, recalls, overspending, or worse. The problem is that these three variables frequently have opposing pulls. Cost-cutting measures may jeopardize safety.

Putting quality first could make your budget go overboard. What then is the best way to strike a balance? This article explains how to balance cost, quality, and safety without sacrificing any of them.

What Is Important for Cost, Quality, and Safety: The connection between safety, quality, and cost is frequently misinterpreted in many industries, but particularly in manufacturing and construction. Many people hold the belief that you must choose between two options. Desire greater safety and quality? Get ready to spend more money.

Do you need to reduce expenses? Quality and safety are frequently the first to suffer. But this way of thinking is a phony compromise. In actuality, safety, quality, and cost are interrelated foundations of a successful operation rather than conflicting goals.

In addition to preventing mishaps and flaws, investing in safety and quality also immediately lowers expenses and improves profitability. If one area is neglected, it will unavoidably cause issues in the others, resulting in rework, delays, mishaps, and harm to one’s reputation.

The important connection between these three components will be examined in this essay. We’ll examine how a robust safety culture improves quality, how cost-effective processes lower expenses, and why putting all three first is the only viable way to achieve long-term success.

The Foundation of Excellence

More than merely a legal necessity, a safe workplace serves as the cornerstone of operational excellence. Feeling safe and appreciated significantly improves employee engagement, morale, and performance. This favorable atmosphere directly impacts cost and quality.

Safety Enhances Quality: Safe environments encourage employees to be more attentive and focused. Employees who receive training on safety procedures form a precision-oriented habit that transfers to other operations. The production of high-quality work is largely dependent on this attention to detail.

Decreased Human Error: Clear communication, established processes, and checklists are common components of safe work practices. In addition to lowering the possibility of accidents, these methods also greatly lower the possibility of expensive errors and manufacturing flaws. Committed employees are less likely to rush or take shortcuts that compromise quality.

Enhanced Employee Engagement: Workers feel taken care of when safety is a true focus. Higher levels of involvement and a stronger sense of ownership over their job result from this. Employee engagement increases the likelihood that they will point out possible problems with quality, recommend changes to the process, and take satisfaction in producing a better end product.

How Safety Reduces Costs

It is impossible to dispute the economic case for safety. The long-term savings greatly outweigh the initial investment required for training, personal protection equipment (PPE), and safe equipment.

Reduced Insurance Premiums: Businesses with excellent safety records and low incident rates are frequently eligible for workers’ compensation insurance rates that are much lower. This can result in significant yearly savings.

Preventing Accident-Related Direct and Indirect Costs: The cost of workplace accidents is high. Medical bills and compensation claims are examples of direct costs. The indirect costs, however, are frequently far higher.

Work stoppages, damaged equipment, time spent investigating accidents, training replacement staff, and a drop in employee morale and productivity are a few of these. According to OSHA, an injury’s indirect expenses may exceed its direct costs by up to 4.5 times.

Lower Employee Attrition: One of the most important aspects of employee retention is a safe workplace. High employee turnover is costly since it involves expenses for employing, training, and recruiting new employees. Making safety a top priority makes talented workers want to stay at your company, which lowers these ongoing costs.

The Factor Influencing Profitability: Building a reputation for dependability and excellence is more important than simply producing a product that satisfies requirements. Processes of superior quality are by nature more effective and less wasteful, which always results in lower costs and a safer workplace.

Do you have a Question?

Get An Auto Glass Replacement Quote Now 866.278.7417

How Quality Improves Safety

A company’s commitment to quality frequently entails spending money on improved supplies, well-maintained machinery, and efficient procedures. These components are essential for occupational safety as well.

Dependable Equipment: A dedication to excellence guarantees regular inspections, maintenance, and replacements of tools and machinery. Well-maintained machinery not only enhances efficiency in producing high-quality products but also significantly reduces the likelihood of malfunctions and accidents.

Simplified Processes: The goal of quality management systems like Lean Manufacturing and Six Sigma is to standardize workflows and cut waste. These well-planned, predictable procedures reduce the likelihood of unforeseen circumstances that could lead to safety mishaps. The workplace is safer when everyone knows exactly what has to be done and how to execute it.

Actively Identifying Hazards: Finding possible flaws before they arise is a fundamental tenet of quality control. Safety is another area where this proactive mentality can be used. Workers who receive quality deviation detection training are also more adept at identifying possible safety risks and taking action before they endanger others.

How Costs Are Decreased by Quality: Although the term “cost of quality” is widely used in the business world, it is frequently misinterpreted. Poor quality is where the true cost lies. Investing in doing something correctly the first time is typically less expensive than fixing mistakes later.

Diminished Rework and Scrap: Rework, errors, and defects are major sources of expense. They don’t bring value; they just use resources, labor, and time. You may lower manufacturing expenses and these issues by implementing robust quality control procedures.

Fewer Warranty Claims and Returns

Higher customer satisfaction and fewer returns or warranty claims are the results of high-quality products. This preserves the reputation of your brand while also saving money on shipping and replacement expenses.

Improved Customer Loyalty and Brand Reputation: Delivering quality on a regular basis helps you gain your clients’ trust. This loyalty results in favorable word-of-mouth recommendations and repeat business, both of which are effective and affordable marketing strategies. Having a solid reputation can also help you charge more for your goods.

Finding the Correct Balance: The secret to building a successful, long-lasting company is to see safety, quality, and cost as interrelated factors rather than conflicting goals. Together, these three elements function to achieve true operational excellence.

Organizations are made stronger, more efficient, and more profitable by leaders who embrace this integrated approach. Begin by integrating safety and quality into your company’s culture, not simply as written policies but as guiding principles that inform every choice.

Invest in your employees by giving them ongoing training, giving them the confidence to voice concerns, and providing them the resources they need to perform their jobs safely and successfully. When you do, you’ll discover that the objectives of a healthier bottom line, a safer workplace, and a better product are not merely compatible; they are one and the same.

Mobile Safe Auto Glass

14241 E Firestone blvd suite 400,

La Mirada, CA 90638

Phone: (562) 608-1154

Toll Free: 1 866 278 7417

Mail: sales@mobilesafeautoglass.com

Get a FREE QUOTE today! You can get a free quote and schedule 24/7 using this free quote wizard.

Mon – Fri 8am – 5pm

Saturday 8am – 1pm

Sunday Closed