Chips and Cracks Windshield Repair for Fleets

Keeping cars roadworthy while keeping maintenance expenses under control is a never-ending task for fleet managers. Windshield repair is one of the most neglected but important parts of fleet maintenance. By Friday, a tiny chip from Monday might grow into a severe crack that could ground a car and cause operational disruptions. Windshield damage affects commercial fleets more often than most managers realize. Highway traffic, construction areas, and prolonged vehicle use create an ideal environment for chips, cracks, and other glass damage. A small annoyance might easily turn into a safety risk, insurance liability, or problem with regulatory compliance. Knowing how to handle windshield replacements effectively for your whole fleet may make the difference between little maintenance costs and significant business interruptions. From detecting damage early to putting cost-effective repair plans into place, this thorough guide will assist you in creating a proactive approach to fleet windshield care.

Get An Auto Glass Replacement Quote Now 866.278.7417

Windshield Replacement & Repair

Our competitors push you into going to their shop to get your glass fixed-making it cheaper for them. We make it easier for YOU to get back on the road by offering free mobile repairs at your home or work. With our free mobile services servicing the entire Orange County & Los Angeles area, we can often handle your windscreen replacement the same day! So the next time you need a windshield replacement, give us a call.

Talk to a Windshield Replacement Specialist Now 866.278.7417

Calibration

Calibration is the process of returning a vehicle’s ADAS to OEM specifications. Calibration is necessary after a new glass installation, particularly a windshield with a camera mounted to it, to ensure that the ADAS features continue to function properly despite having been moved during installation. If a car’s ADAS is not properly calibrated, the system may not function safely. A misaligned camera could jeopardize the functionality of the system and lead to dangerous driving or accidents, so it is crucial that the cameras are aligned perfectly, which is what windshield calibration ensures.

Talk to a Calibration Specialist Now 866.278.7417

Fleet Auto Glass Repair

We provide expert auto glass repair and windshield replacement services for commercial fleets of all sizes. We are experienced with all manufacturers and machine types of domestic or foreign cars, trucks, vans, or commercial vehicles, including heavy equipment. Our same day mobile auto glass and windshield repair service will enable you to get back on the road faster and start saving you time and money instantly. Give us a call today! We are here to help!

Talk to a Fleet Auto Glass Specialist Now 866.278.7417

Knowing About Windshield Damage in Fleets

Compared to private automobiles, commercial trucks are far more likely to meet road dangers. Windshield damage is more likely to occur in fleet cars since they usually accrue more miles, take different routes, and operate in different weather conditions.

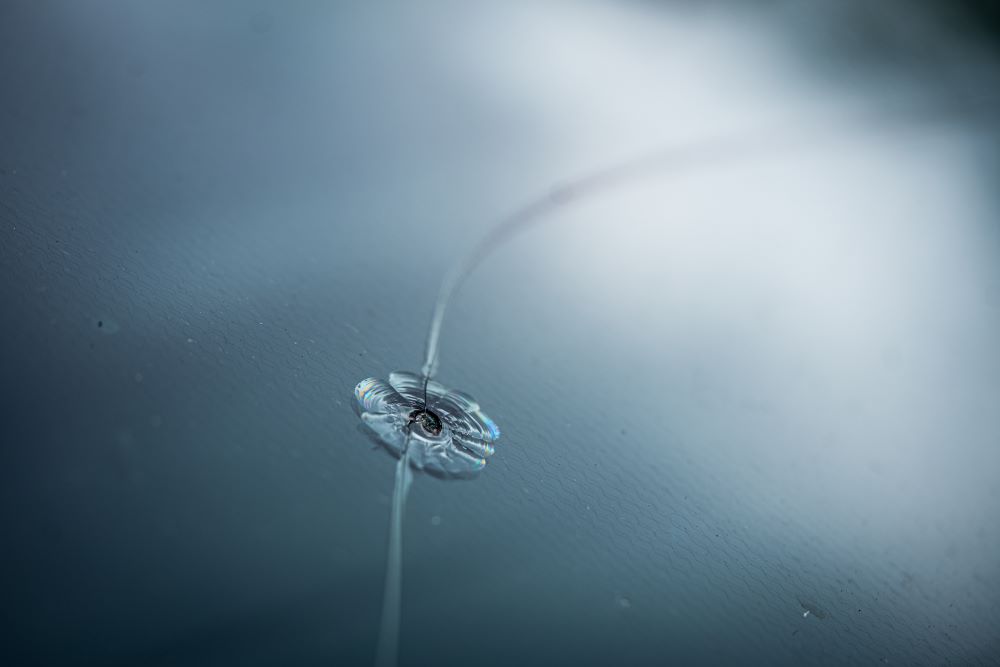

Typical Types of Damage to Fleet Windshields: Stone chips represent the most common type of damage. These tiny impact points typically happen when trash or loose grit hits the windshield while traveling at high speeds. Even though they are little at first, temperature variations and vehicle vibrations can cause stone chips to spread quickly.

Star breaks can be seen when an impact creates numerous cracks that radiate out from a central location. Usually caused by bigger debris hits, they need to be addressed right away to stop them from spreading.

Untreated chips or abrupt temperature changes are common causes of long cracks. Usually, replacement is required whenever a crack exceeds six inches long.

Edge cracks can weaken the glass’s structural integrity and begin close to the windshield’s edge. These need to be evaluated by a specialist right away.

Factors That Hasten Fleet Vehicle Damage

Due to particular difficulties, windshield damage in fleet cars may deteriorate more quickly than in private automobiles. Glass constantly expands and contracts due to prolonged exposure to temperature extremes during long-distance travel, transforming tiny chips into widespread fissures.

Damaged regions are constantly under stress due to highway vibrations caused by heavy traffic and frequent starts and pauses. There is a greater chance of flying debris in construction areas, which are sometimes inaccessible to commercial trucks.

Do you have a Question?

Get An Auto Glass Replacement Quote Now 866.278.7417

The Effect of Ignored Windshield Damage on Businesses

For fleet operations, postponed windshield repairs lead to a series of issues. Impaired visibility puts drivers and other road users at risk of incidents that prompt maintenance could have prevented.

Safety and liability concerns arise: Cracked windshields reduce driver vision, particularly during inclement weather. Broken glass can provide blind spots or skew a driver’s vision of the road. Operating a car with known windshield damage may expose one to negligence claims in the event of an accident.

The state of the windshield is a pass/fail factor in several commercial vehicle inspections. The availability of the fleet is immediately impacted when vehicles that fail inspection are forced to be out of service until repairs are finished.

Problems with Regulatory Compliance: Commercial vehicle windshields must meet certain standards set by the Federal Motor Carrier Safety Administration (FMCSA). DOT inspections may find violations for cracks greater than 1/4 inch in the driver’s crucial visual region.

Although state laws differ, most of them forbid operating commercial cars with windshield damage that obstructs the driver’s visibility. Fines, the seizure of a vehicle, and harm to your company’s safety reputation are all possible outcomes of violations.

Cost Increase: If left neglected, a $50 chip repair might turn into a $500 windshield replacement. This has a significant financial impact when multiplied by a fleet of automobiles. In addition to replacement cars or rental fees, emergency repairs can cost more than planned maintenance.

Creating a Preventative Windshield Care Plan

Reactive measures are not enough for effective fleet windshield management; systematic techniques are needed. Standardized procedures help keep expenses under control and provide uniform upkeep for the whole fleet.

Frequent Inspection Procedures: Include windshield checkups once a week in your pre-trip safety routine. Emphasize that early identification saves money and avoids safety hazards as you train drivers to see damage and report it right away.

Provide a straightforward mechanism for classifying damage so that drivers may express how serious issues are. Minor chipping (less than 1/4 inch), moderate damage (1/4 to 1 inch), and serious damage needing quick treatment are possible categories.

Tracking and Documentation Systems: Keep thorough records of every vehicle’s windshield replacements, repairs, and damage. This information aids in the identification of trends, such as cars that encounter issues frequently or routes with greater damage rates.

Much of this tracking may be automated using digital fleet management systems, which can also automatically schedule repair appointments and provide warnings when damage reports are made.

Setting Priorities for Repairs: Establish precise rules for deciding which repairs should be prioritized depending on the extent of the damage, the value of the vehicle, and timetable flexibility. Some vehicles, like emergency service trucks, might require immediate servicing, while others might require routine maintenance.

Selecting the Appropriate Repair Options

Not every type of windshield damage calls for the same method of repair. Knowing when a repair is feasible versus when a replacement is required can maximize costs and safety.

What are the criteria for deciding between repair and replacement?: It is frequently possible to successfully repair minor chips and cracks under three inches, regaining both structural integrity and optical purity. Repairs may be finished in 30 to 60 minutes and usually cost 80% less than replacements.

When damage reaches the borders of the windshield, is inside the driver’s line of sight, or is larger than what can be repaired, replacement is required. Advanced driver assistance system (ADAS) components included in contemporary windshields may also need to be recalibrated after replacement.

Repair Services on the go: By sending experts to your fleet’s location, mobile windshield repair services save downtime. Many mobile services are especially economical for bigger fleets since they may handle several cars in a single visit.

To prevent operating interruptions, schedule mobile repairs during vehicle downtime or shift changeover. To support fleet operations around the clock, several firms provide after-hours appointments.

Developing Connections with Vendors: Make connections with trustworthy windshield repair businesses that are aware of the requirements of commercial fleets. Seek suppliers who provide fleet-specific services, including bulk discounts, priority scheduling, and thorough repair records.

Particularly for important cars, negotiate servicing contracts that contain guaranteed response times. Some suppliers provide comprehensive fleet plans that include options for preventative maintenance and routine inspections.

Strategies for Cost Management

Strategic planning and vendor agreements are necessary to control windshield repair expenses across a sizable fleet. Preventive maintenance and large purchasing power may drastically lower overall costs.

Discounting by Volume: For fleet clients, the majority of windshield repair businesses provide significant savings. These might include bundled pricing for several vehicles, free service fees, or lower expenses per repair.

Contracts for annual services frequently offer further savings and financial stability. To make cost planning easier, think about negotiating a set price for typical repair types.

Considerations for Insurance: To find out what is covered for windshield repairs, review your fleet insurance policy. Repairs are basically free because many comprehensive plans cover glass damage with low or no deductibles.

In recognition of the lower chance of accidents and more significant claims, several insurers provide extra savings to fleets using proactive glass repair programs.

Preventive Actions: Some actions can reduce the frequency and severity of windshield damage. When feasible, change routes to avoid recognized hazard locations or put protective films on high-risk vehicles.

Driver education programs that emphasize identifying road hazards and maintaining safe following distances can also reduce damage incidences.

Integration of Technology and Fleet Management

Contemporary fleet management systems can streamline windshield repair procedures through automation and data analysis. Integration with current systems enables comprehensive vehicle health monitoring.

Reporting Digital Damage: Drivers may promptly report and take pictures of windshield damage using mobile applications, giving them real-time fleet status visibility. By automatically recording position data, GPS integration makes it easier to see damage trends by area or route.

Without human involvement, automated workflows are able to arrange appointments, prioritize repairs, and monitor completion status.

Analytics for Prediction: The ability to identify cars or routes with greater damage rates through historical data analysis enables proactive planning and resource allocation. Seasonal trends may indicate the best time to conduct more frequent inspections or take preventative action.

Additionally, predictive models can assist in optimizing maintenance budgets and forecasting future repair costs.

Take Fleet Windshield Maintenance action: Maintaining your windshields properly lowers operating expenses, protects your drivers, and guarantees regulatory compliance. Begin by putting in place routine inspection procedures and building connections with certified repair suppliers.

To create baseline data, record the windshield conditions of your whole fleet. You may use this data to monitor progress and convince stakeholders that maintenance expenditures are worthwhile.

To test new procedures and gauge outcomes before implementing them throughout the fleet, think about implementing a pilot program with a selection of cars. The data from successful pilots can support funding proposals and wider program adoption.

Remember, maintaining your windshield not only saves money but also enhances operating effectiveness and safety. Proactive initiatives lead to reduced replacement costs, increased vehicle availability, and enhanced driver safety.

Why Quicker Windshield Repair Solutions Are Needed for Commercial Vehicles

Every minute a commercial vehicle remains idle costs money. When a construction vehicle sustains glass damage on a job site or a delivery truck’s windshield cracks on a busy route, it results in missed productivity and growing costs. However, many fleet managers continue to use antiquated windshield repair techniques, which can take hours or even days to finish.

The commercial vehicle business, with its extremely narrow profit margins, immediately converts time into profit. A commercial truck’s lost income from a single day of downtime can range from $500 to $1,000, not accounting for the impact on delivery schedules and client satisfaction. Because of this fact, prompt, dependable windshield repair is not just a convenience but also a must for businesses.

Conventional windshield repair often results in extended vehicle outages, causing significant disruptions to fleet owners’ schedules. Although mobile repair services have become a viable option, a complete replacement might still take several hours to do. The industry needs repair solutions that put speed first without sacrificing quality or safety.

Do you have a Question?

Get An Auto Glass Replacement Quote Now 866.278.7417

The Real Price of Downtime Due to Windshield Damage

Downtime for commercial vehicles has far-reaching financial effects that go well beyond the immediate cost of repairs. When determining the overall cost of windshield damage, fleet managers need to account for a number of different expense categories.

Loss of Direct Revenue: If a business truck isn’t moving, it’s not making money. A truck that travels 500 miles a day loses $200 to $300 in gross income for every day it is out of service, as long-haul truckers usually make between $0.40 and $0.60 per mile. When assessed per delivery, the lost income for local delivery vans that make several stops might be significantly more.

Scheduling and Driver Compensation: Drivers require payment even when their cars are undergoing repairs. Fleet management is forced to alter set routes and timetables by either paying drivers to wait or reassigning them to other vehicles. This juggling act frequently results in overtime expenses as other drivers cover more ground.

Impact on Customers and Reputation: Delays in deliveries can harm customer relationships and potentially result in fines or contract termination. Dependability is crucial in logistics. The full cost of downtime is difficult to measure but might be huge because a single missed delivery window can ruin relationships that have been built over years.

Present-Day Fleet Windshield Repair Issues

Fleet managers face unique challenges related to windshield damage that consumer vehicle owners rarely encounter. The size of activities and the necessity of maintaining vehicle traffic are the main causes of these difficulties.

Geography plays a significant role in dispersion: Far from their home base or preferred service providers, commercial trucks frequently break down. A truck with windshield damage in a distant area may face longer wait periods and fewer repair alternatives. This geographic difficulty is especially severe for over-the-road trucking firms that have drivers operating in many states.

Complexity of Scheduling: Careful preparation is necessary to avoid operating disruptions while coordinating maintenance for many vehicles. When scheduling repairs, fleet managers need to take delivery obligations, driver schedules, and vehicle availability into account. Commercial operations often require a level of urgency that traditional repair shops cannot meet.

Documentation and insurance: Compared to personal automobiles, commercial vehicle repairs entail more intricate insurance procedures and paperwork needs. Throughout the repair process, fleet managers are responsible for making sure that the correct documentation is done and that the vehicles continue to comply with Department of Transportation rules.

Advantages of Quick Windshield Repair Services

For commercial vehicle operators that value efficiency and cost management, quick windshield repair technologies and services have strong benefits.

Quick windshield repair services reduce disruption to operations: Speedy repair methods allow vehicles to return to operation in a matter of hours, rather than days. This speed lessens the chain reaction of delays that can affect client commitments and complete delivery schedules. With just minor modifications to predetermined routes and schedules, fleet managers can keep up their operational pace.

Lower Labor Expenses: Repairs completed more quickly allow drivers to spend more time making money and less time waiting. Because of this efficiency, there is less need for overtime coverage, and the expenses related to driver downtime are eliminated. Without increasing their personnel to make up for cars that are out of commission, fleet operators can maintain productivity levels.

Increased Adherence to Safety Regulations: Contemporary fast repair solutions frequently adhere to the most recent industry requirements and include cutting-edge safety measures. This reduces the risk of additional damage or safety issues during the repair process, while ensuring that commercial vehicles meet Department of Transportation standards.

Technological Advancements Fueling Quicker Repairs

The windshield repair sector has used a number of technology advancements that drastically cut down on repair periods for commercial cars.

Superior Adhesive Technologies: While retaining their excellent strength and durability, new polymer-based adhesives cure more quickly than conventional materials. Vehicles may return to service sooner because of these advancements, which enable windshield installations to attain complete structural integrity in a tenth of the conventional cure time.

Mobile Repair Facilities: Advanced mobile repair trucks deliver full windshield replacement services right to fleet locations or accident scenes. These facilities boast climate-controlled workspaces and specialized equipment that rivals or surpasses that of conventional repair shops.

Scheduling and Digital Integration: Modern repair businesses use digital platforms to expedite scheduling, inventory control, and fleet manager communication. Fleet operators are kept informed throughout the repair process through automatic updates and real-time tracking, which improves operational planning.

Selecting the Best Partner for Rapid Repair: It’s important to carefully consider a number of variables when choosing a windshield repair provider, not simply service speed.

Coverage by Region: Select repair partners who are available around the clock and have a wide geographic reach. To guarantee that cars can receive timely maintenance wherever they are, the ideal supplier should provide consistent service quality across the various locations where your fleet operates.

Experience Particular to the Fleet: Seek out suppliers who have a track record of working with fleets of commercial vehicles. These experts can satisfy fleet operators’ scheduling restrictions and regulatory requirements since they are aware of the particular needs of various vehicle types.

Certifications and Quality Assurances: Make sure prospective repair partners provide thorough guarantees on their work and maintain the appropriate certifications. If the quickest solution jeopardizes safety or necessitates more service calls to correct flaws, it isn’t worth it.

Taking Fleet Windshield Repair Action

Astute fleet managers understand that their windshield repair plan has a direct effect on their financial results. To ensure prompt response times when cars require repairs, it is crucial to establish partnerships with rapid repair providers prior to damage occurring.

Assessing your present maintenance procedures and figuring out the actual cost of vehicle downtime in your business should be your first steps. Next, look into quick repair possibilities in your main operating areas, paying particular attention to companies who can guarantee response times and comprehend the needs of commercial vehicles.

To reduce the frequency of damage, think about putting preventive measures in place like routine windshield checks and driver education. Having a quick and dependable fix in place, however, may make the difference between little operational disruptions and significant financial losses when repairs are required.

The commercial vehicle sector is constantly changing to become more efficient and have less downtime. In an increasingly competitive industry, fleet operators who use quick windshield repair solutions set themselves up for greater client satisfaction and profitability.

Mobile Safe Auto Glass

14241 E Firestone blvd suite 400,

La Mirada, CA 90638

Phone: (562) 608-1154

Toll Free: 1 866 278 7417

Mail: sales@mobilesafeautoglass.com

Get a FREE QUOTE today! You can get a free quote and schedule 24/7 using this free quote wizard.

Mon – Fri 8am – 5pm

Saturday 8am – 1pm

Sunday Closed